Printing With Plastic: The 3D Printing Process

March 17, 2023

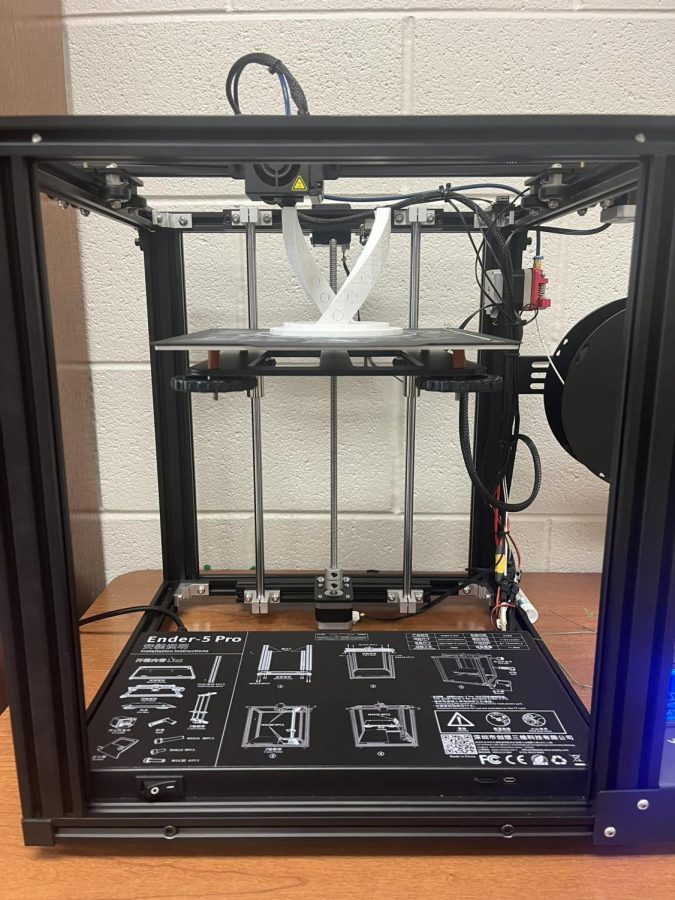

There are many ways to produce things we need and want in this world and you can make many of them right here at Lincoln-Way West. A program by West Library offers a cheap and effective way to create using 3D printing. 3D printing is very complicated, but it is also fast and accurate. 3D printing comes in many forms such as SLA and CNC. For simplicity, we will be focusing on FDM. The process is simple. Paste very hot plastic onto a surface to meld with the surface, or for our welders, it’s like welding over welds over welds! With 3D motion it can paste plastic to form a 3D shape. This simple process can make anything from basic boats to concrete houses. The library provides this service to the students and faculty. Such a program seems simple, right? Print what the students want. However, it is like a machine with 100 switches affecting four things: time, quality, plastic, and human effort. Prints take hours and sometimes even days if they have many parts. Time, speed, and size affect the number of prints and what print can be made. That affects the quality of the print and how many hours are spent physically “cleaning” the prints, as it’s referred to.

Finally, plastic, it’s not cheap. It can be $16-$20 a kilogram so we try to reduce the plastic as much as possible and this has a benefit of taking less time. The person running this service is myself, Noah. I organize, maintain, manage, and clean the entire program and machines. This job takes a lot of computer wizardry, so I have automated some processes to be done by Excel’s “function” feature. Prints will be accepted if they follow school rules so. Originally, I thought about a Jell-O mold, however, I was told the plastic type used “PLA”, which was not food safe. So, sadly I settled on a name tag. Originally, I thought that 3D printing was fast, however, it is not. It’s a multi-hour process that has many limits. Even attempting mass production is futile because each printer needs to be manually programmed, calibrated, loaded with plastic, checked for issues, diagnosed for issues, and fixed for issues. For example, one of the printers is down due to an issue that has seemingly no explanation. However, these limitations don’t take away from the feel of a perfectly printed part!

Visit the library to make a request or use the link below. The library is also in need of students to learn the process to print and help others. 3D Print request form (Page 1 of 3) (office.com)